As we enter the holiday season, a time for celebrating the blessings in our lives and reflecting on what we are grateful for, it’s also a moment to dream about the future and the opportunities that lie ahead. As we close out another year here at Creamer, I believe it’s important for us to reflect on what we are thankful for and share our vision for the future.

For me, first and foremost, our gratitude begins with the health and safety of our people. From our front line field leaders to our dedicated back-office teams, their well-being is our number one priority. Two years ago, we set out on a journey to make this a central focus of our culture. It started with aligning our leadership on the “why” and has evolved into a series of initiatives across the organization. While this journey is far from complete and we expect bumps along the way, we’ve already seen significant progress—and I am excited to say that 2024 is shaping up to be one of the most successful years in our 100+ year history.

A key metric of our progress is our Total Recordable Incident Rate (TRIR), which measures our safety performance. Before starting this journey, Creamer’s TRIR hovered around 1.6-1.8, already significantly better than the industry average of ~2.3. In 2023, after just one year of focused effort, we reduced that number to 1.2—the lowest incident rate in our history. In 2024, we’re tracking similar at 1.2, with the potential to dip below 1 for the first time ever. But more than the numbers, what truly matters is the impact on the people we care about: our team members. These improvements mean they are more likely to go home at the end of each day as healthy and happy as when they arrived. As the leader of this organization, there is no greater satisfaction than writing that.

When it comes to well-being, we also look to our annual employee engagement survey, which gathers feedback across the entire organization. Based on responses from 2023, we implemented a significant budget for each department to strengthen connections within their teams outside the office. From Top Golf and escape rooms to Formula 1 racing and even music concerts, the impact has been incredible. These events have created authentic bonds and fostered relationships built on trust and mutual support. They’ve also been a lot of fun!

Another source of pride for me as I reflect on our journey is our growth. Over the years, we have been fortunate to expand into a half-billion-dollar organization, primarily operating within a relatively confined geographic

footprint in the Northeast—covering southern New York, New Jersey, eastern Pennsylvania, Maryland, Delaware, and northern Virginia. How did we achieve this? Two things come to mind, beyond the strength of our people, which I’ve already highlighted: our partnerships and our diversity.

When I speak of partnerships, I refer not just to client relationships but also to our joint ventures, vendor collaborations, and subcontractor connections. These are long-standing partnerships built on mutual respect, trust, and a shared vision of success. The success of these partners is our success, and vice versa—a concept that is simple yet not always easy to implement. We are fortunate to have such incredible partners—too many to name, but if you are reading this, you are likely one of them.

Diversity also plays a key role in our success, particularly the diverse markets we serve. Our ability to adapt to the evolving needs of our clients has been a major differentiator. This adaptability is one of the reasons we invested in the Joseph T. Walsh Leadership & Training Center, recognizing the need to continuously develop our field leaders’ capabilities across a wide range of business lines. The skills required to lead a crew today go far beyond knowing how to build a project from a plan sheet. They must be adept at interacting with clients, the general public, leverage cutting-edge technology, and navigate a rapidly changing industry. Having our own training center gives us the flexibility to tailor training to meet these needs and support the demands of our partners.

But as much as we value our past, we must also look to the future with a clear vision of where we are headed. While our people will always be at the core of our success, our focus will extend beyond their health and safety to their continued development. If we grow our people, we believe the company will grow along with them. To this end, we will continue our focus on building a world-class leadership development culture to ensure that we have a deep bench of talent and leaders at every level, ready to drive our success. We plan to implement an accelerated recruiting, training, and development program to ensure that our future leaders are ready for the challenges ahead.

Additionally, we will double down on our partnership and diversity strategy by expanding our lines of business within each office. We will empower leaders in each region to conduct ongoing research to identify both our partners’ needs and opportunities to enhance our infrastructure. By developing innovative solutions to meet these needs, we can not only expand our business but also create new capabilities within our existing geographic footprint.

This is an exciting time to be part of the Creamer team. We have much to be thankful for, and our leaders should be proud of the accomplishments in 2024. Looking ahead, the future is bright, and while our strategic plans are important, what excites me most are the opportunities ahead, driven by our people and the value they bring to our partners across all our diverse offerings.

I wish you all a happy holiday season and a prosperous New Year. Thank you for your continued support.

– Martin Downs, Jr

President

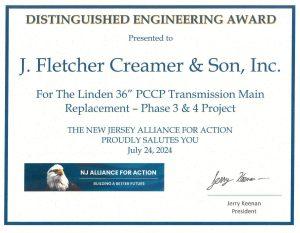

J. Fletcher Creamer & Son, Inc. was honored with an Alliance for Action Distinguished Engineering Award for the Linden 36” PCCP Transmission Main Replacement – Phase 3 & 4. This award celebrates Creamer’s significant role in enhancing water infrastructure alongside New Jersey American Water and Kiely Engineering.

.

.

The project’s scope involved replacing approximately 7,300 feet of an aging 36-inch water main in Linden, New Jersey. Originallyinstalled in the 1950s, this vital piece of infrastructure hasexperienced frequent breaks, impacting both cost and service reliability. The new main installation will support a dependable water supply and fire protection for the community. There was no room for error during coordination and installation due to one of the largest water customers of New Jersey American Water being supplied by this pipeline.

Under the guidance of Project Manager Daniel Nowak, along side Superintendent Evan Watson and Estimator Terrell Maroney, Creamer implemented innovative solutions to complete the complex project. Foreman Alex Cuevas and his crew installed critical infrastructure, including 36” and 48” insertion valves and cured-in-place lining, which was challenging due to the project’s location within a congested area, not to mention a very strict timeline. Coordination with Merck Pharmaceuticals ensured zero disruptions to their operations, while still maintaining the schedule and finishing the project on time.

The high value project, which commenced in November 2023, exemplifies J. Fletcher Creamer & Son, Inc’s. dedication to infrastructure renewal and community service, was completed in June of 2024.

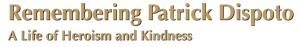

Patrick Dispoto was not just a colleague at J. Fletcher Creamer & Son, Inc. – he was a cherished friend, a mentor, and a family member in spirit. His kindness, warmth, and unwavering dedication to others left an indelible mark on ever one who knew him. Pat’s life was tragically cut short in an act of extraordinary bravery, leaving a void that will never be filled.

On that fateful day at Seaside Park, as dark clouds gathered and lightning loomed, Pat’s instinct was not to protect himself but to ensure the safety of others. After guiding his girlfriend, Ruth, to the safety of their truck, he returned to the beach to warn others. It was there, in an unselfish act of courage, that Pat was struck by lightning. This final act of heroism encapsulates the kind of person he was: selfless, brave, and deeply caring.

Pat joined the Creamer family in 2010, leaving an immediate and lasting impression. Peter Smith, Vice President of Estimating, recalled their first meeting with a fond smile: “Pat was one of the first guys I hired. He came highly recommended, and from day one, he was a light in the office. He had this way of making people feel valued, of making you want to be better just by being around him.”

For Dominick Quartuccio, a recently retired Senior Estimator, Pat was much more than a coworker. “Pat was my rock,” Dominick shared, his voice tinged with emotion. “We used to call him ‘Elmer’ at our old company because he was the glue that held everything together. But more than that, he was my friend. He was the guy you could count on, the one who would drop everything to help you.”

Jeff Faiella, Chief Estimator, reflected on the unique bond he shared with Pat. “He wasn’t just a colleague; he became like family to me. Whether it was helping with a tough project or laying sod in my yard, Pat was always there. His heart was so big. Losing him is like losing a part of myself.”

Pat’s legacy extends far beyond his professional achievements. Hundreds of tributes poured in after his passing, a testament to the countless lives he touched. His colleagues, friends, and loved ones remember him as a beacon of positivity, a man who lived to uplift others.

Peter Smith’s words resonate deeply with those who knew Pat: “It will take more than one person to fill his shoes. Pat was a rare soul – someone who leaves the world better than they found it. We’ll miss him every single day.”

Pat’s courage and kindness remind us of what it means to live selflessly. His memory will forever be etched in the hearts of his family, friends, and everyone fortunate enough to have crossed his path.

J. Fletcher Creamer & Son, Inc. is nearing the completion of a significant infrastructure upgrade project for New Jersey American Water in North Plainfield. This Spray-in-Place Pipe (SIPP) project, applying

NSF-Approved Epoxy manufactured by Warren Environmental, involves cleaning, CCTV inspection, and epoxy lining of over 11,000 linear feet of water mains to ensure cleaner, more reliable water service for the community. With a completion date set for December 31, 2024, this endeavor reflects Creamer’s commitment to delivering innovative and efficient solutions for aging infrastructure.

The residents and commercial customers that make up the densely populated municipalities of New Jersey rely on the aging infrastructure, which is rapidly approaching the end of its useful life. Increases in demand for water and wastewater needs are putting a stress on the current systems. New Jersey American Water is one of the progressive utilities looking at alternatives to dig and replace. Trenchless rehabilitation provides safer working conditions, less invasive to the general public, lower project costs and less environmental impact than open-cut methods.

The SIPP process involves centrifugally spraying, also known as Spin Casting, to coat the inside of the host pipe with durable materials like cement mortar, polyurea, or epoxy. Creamer’s Spray Rig offers computer-precision application of the sprayed epoxy, complete with real-time monitoring of installation data.

This technology allows the applicator to actively monitor the quality by controlling variables such as the mix ratio and temperature of the coating. The speed at which the spray head is pulled through the pipe is calculated by the onboard computer. Adjusting this speed based on the pipe’s size enables precise control of the coating thickness for optimal durability and longevity.

The project scope covers a wide range of essential tasks, from bypass installation and temporary service connections to the replacement of galvanized water services and the installation of new fire hydrants. A crucial part of this project is the epoxy lining of the water mains, which ensures long-term protection against corrosion, reducing future maintenance needs and extending the lifespan of the water distribution system. Pipe rehabilitation also improves water quality, enhancing the pipe asset and reduces pumping costs.

Led by Project Managers Henri DeFrance and Jeremy Paul, Superintendent Evan Watson, Estimator Dave Koger, and Project Engineer Daniel Nowak, the Creamer team has already achieved significant milestones. The

cleaning and epoxy lining of 6-inch and 12-inch water mains—covering a total of 9,800 and 1,400 linear feet, respectively—is 100% complete. The bypass system, which involved the installation, maintenance, and removal of 25,000 linear feet of temporary bypass piping, has also been successfully completed. This system allowed the team to provide uninterrupted water service while the existing pipes were being rehabilitated.

In addition, the installation of 16 new fire hydrants is complete, enhancing local fire protection capabilities. When complete, the team will have installed 4,600 linear feet of new 8-inch piping, with 90% of this work already finished. Road restoration efforts are well underway, with 60% of the roads affected by construction now fully restored. The galvanized service replacement is progressing, with one-third of the work completed out of the planned 130 replacements.

Facing various technical challenges such as coordinating 55 access pits and managing a complex temporary bypass system, the project team, with meticulous planning by Superintendent Evan Watson, has kept the project on track. The successful timely completion of the project underscores the team’s dedication and technical expertise.

This project is proof of Creamer’s commitment to innovation and excellence, and the hard work of the project team has been instrumental in driving its success. As the completion date draws near, Creamer

remains dedicated to delivering the highest quality results for New Jersey American Water and the residents of North Plainfield.

J. Fletcher Creamer & Son, Inc. is proud to have been a key part of the Princeton Meadows Wastewater Treatment Plant (WWTP) project, a significant infrastructure initiative in Plainsboro, New Jersey. The project is designed to replace an aging facility with one that meets the area’s growing needs and complies with upcoming environmental regulations. Since the new plant began processing wastewater this summer, “it has operated smoothly, handling all wastewater flow, allowing the existing plant to be completely shut down and prepared for decommissioning” said Project Manager Chuck Bycroft.

This successful project has garnered significant recognition, recently earning an Alliance for Action Distinguished Engineering Award. This award reflects the high standard of engineering and dedication to sustainability upheld by Creamer and its partners in every aspect of this endeavor.

Under the leadership of our skilled Creamer project team—Chris Mabie, Jakub Pustkowski, Dan Mattos, Jack Downey, and others—alongside foremen Liandro Grego, Jason Wunder, and Phil Zehrer, we were able to shave one month off the overall project schedule by shortening the transition period to the new facility, achieving operational goals sooner than anticipated.

The plant’s recent lab results have confirmed that it operates fully within both the current regulatory limits and the updated New Jersey Department of Environmental Protection (NJDEP) permit requirements set to take effect at the end of the year. This compliance is a testament to the plant’s efficient design, which enables it to treat up to 1.7 million gallons of wastewater daily using advanced filtration, ultraviolet disinfection, and oxidation ditch treatment.

As decommissioning efforts progress at the old plant and site restoration nears, the Princeton Meadows WWTP is evidence of Creamer’s commitment to quality construction and environmental stewardship. We’re honored to receive the Alliance for Action award for this project, and to have played a role in delivering world class infrastructure that will benefit Plainsboro’s environmental future for many years to come.